Vending Solutions for Factories & Industrial Workspaces

- Vendekin Team

- Jan 22

- 3 min read

Factories run on rhythm shift changes, line breaks, strict safety, and zero-tolerance for downtime. The right vending machine for factories does more than sell snacks: it trims walk-away time, enforces PPE availability, supports shift subsidies, and keeps Finance/IT audit-ready. Below is a practical playbook to choose hardware, payments, and cloud controls that fit industrial floors.

Why factories need purpose-built vending

Reduce lost minutes: Nearby access to water, hydration, and quick calories cuts line drift.

PPE & hygiene readiness: 24/7 access to gloves, masks, earplugs, and sanitizers logged for audits.

Shift-aware pricing/subsidies: Entitlements by department/time window for fair, policy-driven benefits.

Audit & compliance: Temperature logs (for chilled), consumption trails (for PPE), and maker–checker approvals.

What to look for in a factory-grade stack

1) Hardware fit

Elevator dispensing (Elevend): Gentle delivery for bottles, jars, lunch boxes, OTC.

Multi-zone cooling: Ambient/chilled/frozen set-points with live telemetry.

Industrial durability: Tamper/tilt alarms, cage options, metal keypad/pickup bay, stable casters.

Large capacity: To handle peak demand at shift start/end with fewer refills.

2) Payments that work on the shop floor

UPI dynamic QR (UPI App like: PhonePe/GPay) for contract/temporary staff.

RFID staff wallets/ID cards for permanent staff with time-windowed subsidies (e.g., ₹X off during 12:00–12:20 lunch).

Optional cards for admin areas and visitors.

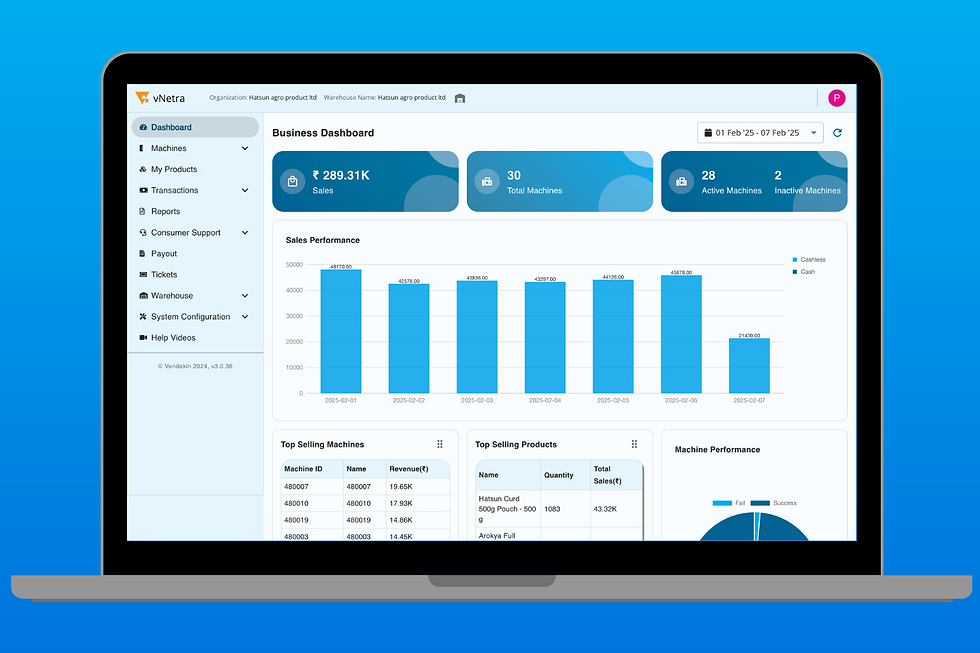

3) Cloud control (vNetra)

Live ops: Online/offline, temp drift, motor errors, door events.

Inventory intelligence: OOS risk, planogram suggestions to reduce dead space.

Entitlements engine: Map SKUs/subsidies by department/shift; export consumption logs.

OTA at scale: Push prices, content, firmware; maker–checker approvals for governance.

Finance comfort: Unified UPI/RFID settlements, refunds/void logs, tax-ready exports.

Recommended Vendekin models for industrial sites

Combo 10 / Combo 22: High-mix snacks & beverages near lines and breakrooms; multi-vend cart for faster queues.

Elevend 22: Elevator dispensing for glass bottles, meal trays, OTC/care items.

Frozen 22 (select plants): Ice-creams and heat-and-eat for night shifts; tight temp control with alerts.

Hygiene & PPE configs: Shelving/coil choices for gloves, masks, earplugs; optional vending cage.

Factory use-cases (proven patterns)

A) Shift hydration + quick calories

Top SKUs: 250–500 ml water, isotonic drinks, tea/coffee cans, energy bars.

Multi-vend combos: “Water + snack ₹10 off” during breaks to clear queues quickly.

B) PPE & hygiene access

Stock gloves, masks, earplugs, hairnets, sanitizer pouches.

RFID entitlement: 2 pairs/gloves per shift per operator; logs exportable for audits.

C) Canteen relief & off-hours access

Frozen desserts or heat-and-eat when kitchen shuts; elevator delivery prevents damage.

Ops & safety playbook

Placement

Close to lines but outside material movement lanes; ensure CCTV coverage; keep 1–2 m clear for queueing.

Hygiene & uptime

Daily wipe of glass/pickup bay; weekly sanitize dispense path/elevator tray.

Brush condenser fins weekly; door-gasket inspection to save kWh.

Refill windows

Align with pre-break periods; use vNetra OOS risk to plan clustered routes across bays/buildings.

Security

Tamper/tilt alarms; optional cage; MAC-whitelisting/TLS on network.

Cost & ROI (why factories see faster payback)

Lower walk-away time: Nearby machines cut non-productive minutes.

Shrink control: Elevator + learning planograms reduce breakage/expiry.

Predictable finance: Cashless (UPI/RFID) simplifies settlements and reduces disputes.

Energy discipline: Multi-zone set-points + condenser hygiene lower kWh.

Illustrative math (Combo 10):

85 tx/day × ₹30 × 26 days = ₹66,300 revenue/mo

COGS @ 66% = ₹45,084;

Opex (logistics, energy, routine care, software, fees) ≈ ₹2,000

Net ≈ ₹19,216/mo → Capex ₹1,70,000 → Payback ≈ 8.8 months

Your numbers will vary by footfall, mix, and subsidy policy.

IT & Finance checklists (ask your vendor)

IT/Security

Signed firmware, encrypted storage, staged OTA with rollback.

RBAC in vNetra; audit trail for price/content changes.

Network options: SIM/Ethernet/Wi-Fi, TLS, MAC whitelisting.

Finance

Daily EOD with UPI/RFID rollups; refund/void logs; GST-ready exports.

Entitlement reports (PPE issuance by department/shift); retention settings.

30-60-90 day rollout

Days 1–30 (Pilot)

2–3 machines at high-footfall bays; enable UPI + RFID; set shift subsidies; baseline payment success and stockouts.

Days 31–60 (Optimize)

Turn on planogram suggestions; add multi-vend combos; cluster refill routes via OOS risk.

Days 61–90 (Scale)

Expand to other bays/buildings; lock pricing/subsidy templates; schedule quarterly reviews (AOV, OOS hours, kWh/machine, PPE issuance).

Why Admin Heads choose Vendekin

One partner, end-to-end: Hardware, cashless, vNetra cloud, install, training, and support.

Shift-aware governance: RFID entitlements and maker–checker approvals.

Industrial reliability: Elevator dispensing, multi-zone control, tamper alarms.

Faster payback: Multi-vend UX + data-led planograms boost revenue without extra staff.

Conclusion & Next Steps

A factory-ready vending machine for factories shortens queues, enforces PPE readiness, and keeps audits clean without adding headcount. Vendekin’s hardware + vNetra gives Admin Heads policy-driven control with predictable uptime.

Comments