How to Maintain Your Smart Vending Machine for Peak Performance

- Abhishek Sharma

- Sep 10, 2025

- 3 min read

Updated: Sep 25, 2025

Smart vending machines deliver 24/7 convenience if they’re maintained like the connected retail devices they are. This practical guide gives your ops team a simple, time-boxed routine to protect uptime, food safety, and payment success across mixed fleets (snacks, beverages, hygiene/OTC, and frozen). It also shows how Vendekin’s vNetra helps you move from reactive fixes to predictive care.

Vending Machine Maintenance: Daily Checklist (5–7 minutes)

Wipe touchpoints & screens: Use food-safe, non-abrasive cleaner; dry microfiber finish.

Cashless/payments quick test: Scan UPI QR with PhonePe/GPay, tap RFID staff card, confirm receipt.

Visual inspection: Doors close flush, no ice build-up, no product leaning out of spirals.

Out-of-stock flags: Refill fast-moving SKUs; follow FIFO for dated items.

Error lights & vNetra alerts: Acknowledge, create ticket if needed.

Weekly Tasks (15–20 minutes)

Sanitize dispense path & elevator/elevend tray: Prevent residue and packet tears.

Spiral/elevator test vend: 2–3 SKUs across shelves; check smooth drop/elevator placement.

UI/content check: Promo cards, pricing, and language settings are correct for the location.

Gasket wipe & door seal check: Keeps cold air in and power bills down.

Monthly Tasks (30–45 minutes)

Temperature calibration: Verify each zone set-point (e.g., beverages 2–6°C; frozen ≤-18°C). Log in vNetra.

Condenser dusting: Brush/vacuum fins; improves cooling and compressor life (extra important in summer/monsoon).

Firmware/OTA updates via vNetra: Apply security patches, device drivers, and UI improvements.

Planogram tune-up: Use sell-through data to increase facings for top SKUs; retire slow movers.

Cable & earth check: Look for frays/loose plugs; ensure dedicated grounded outlet.

Quarterly/Seasonal Deep Clean

Full cabinet clean: Shelves, guides, sensors, and drip tray; defrost if required.

Re-grease moving parts (as specified): Elevator rails, motor shafts only approved lubricants.

Health & safety audit: Update cleaning logs, expiry checks, and temperature records for compliance.

Temperature-Controlled & Frozen Care (Multi-Zone Best Practices)

Zone discipline: Don’t mix ambient SKUs into chilled rows or vice-versa; it confuses sensors and hurts cooling.

Door-open discipline: Keep loading windows short; stage refills in crates first.

Ice build-up watch: If you see frost on the evaporator, schedule a controlled defrost and log it.

Payment System Maintenance (UPI + RFID)

UPI QR health: Screen clarity matters clean glass; verify live QR cycles to PhonePe/GPay.

Reader resets: Power-cycle payment terminal monthly to clear caches; confirm settlement batches in reports.

RFID wallets: Test a sample of staff cards from different departments; re-map entitlements if roles changed.

Receipts & audits: Use vNetra to reconcile daily totals vs. bank settlements for faster finance closure.

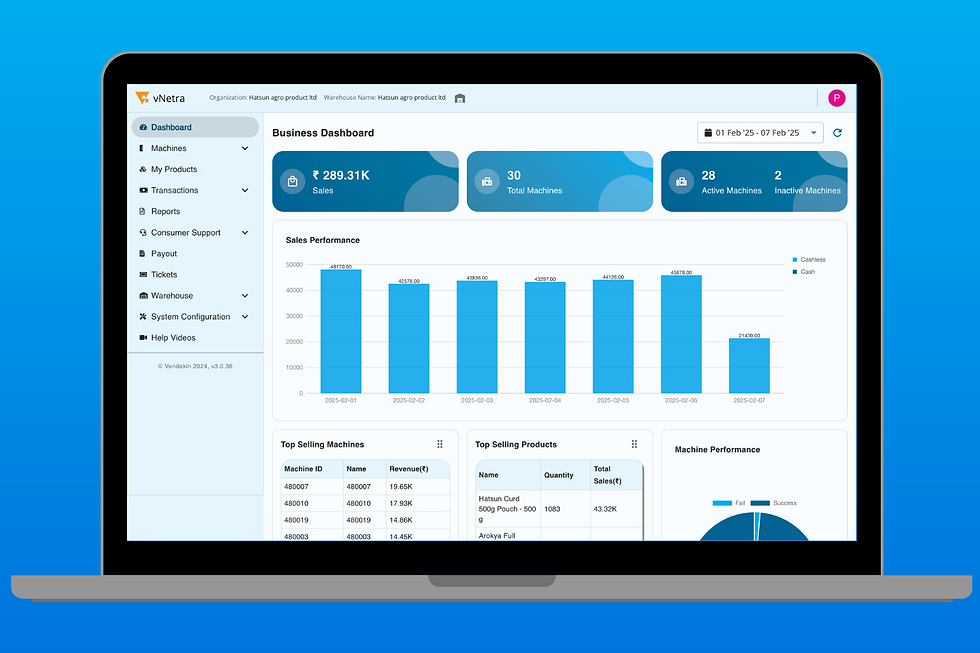

Remote Monitoring with vNetra (From Reactive to Predictive)

Live telemetry: Online/offline status, door events, temperature drift, motor errors see issues before users do.

Auto-tickets: Create service jobs directly from alerts; attach photos/notes from the field app.

Data-driven planograms: Heatmaps reveal dead space; A/B test facings and bundles without site visits.

OTA everything: Push price changes, promos, and firmware fleet-wide in minutes.

Troubleshooting Quick Fixes (Save a Service Call)

Item not dispensing: Check product alignment and spiral tension; test vend in Service Mode.

Reader shows error: Reboot terminal > check network > retry with PhonePe/GPay; raise ticket if EMV kernel error persists.

Cabinet warm: Verify door seal, condenser dust, zone set-points; listen for fan/compressor.

Frozen door stuck: Pause sales in that zone via vNetra; defrost cycle per SOP.

UI frozen: Soft reboot HMI; if recurring, apply pending OTA and log incident.

Your On-Site Spares & Consumables Kit

Microfiber cloths, food-safe cleaner, compressed air can, spare spirals/couplers, gasket strip, fuses, a tested RFID card, and a labeled brush for condenser fins.

AMC for vending machines: what your pack should cover

An AMC (Annual Maintenance Contract) stabilizes OPEX and locks in SLAs ideal for hospitals, campuses, and multi-site offices.

Typical inclusions:

Quarterly preventive maintenance visits (cleaning, electrical, refrigeration, payment module checks)

Priority response for breakdowns (e.g., 8 business hours in metros, 24 in Tier-2/3)

Remote diagnostics & proactive part replacement based on alarm trends

Consumables (gaskets, filters, desiccants) and labor covered; parts either included or discounted depending on tier

Uptime reporting and a quarterly performance review to optimize planograms and prices

Tip: Align AMC windows with your peak seasons (admissions, festival months) and agree on SLA credits if uptime falls below target.

Conclusion

Disciplined vending machine maintenance is the lowest-cost way to unlock higher revenue and longer asset life. A simple cadence (daily wipe-downs, weekly airflow and temperature checks, monthly firmware & hardware inspections) plus a well-structured AMC will keep your vending machine fleet cold, clean, connected—and profitable.

Comments